| Profile Dimensions | Minimum Hole Diameter | Internal Hole Diameter | ||||||

|---|---|---|---|---|---|---|---|---|

| O | ☐ | 1 | 2 | 4 | 1 | 2 | 4 | |

| < 15 mm | < 15 mm | < 20×10 mm | ⌀ 8 mm | ⌀ 14 mm | ||||

| < 20 mm | < 20 mm | < 30×15 mm | ⌀ 8 mm | ⌀ 16 mm | ||||

| < 30 mm | < 30 mm | < 40×20 mm | ⌀ 12 mm | ⌀ 10 mm | ⌀ 25 mm | |||

| < 40 mm | < 40 mm | < 50×39 mm | ⌀ 14 mm | ⌀ 12 mm | ⌀ 30 mm | |||

| < 50 mm | < 50 mm | < 60×40 mm | ⌀ 16 mm | ⌀ 12 mm | ⌀ 10 mm | ⌀ 40 mm | ⌀ 25 mm | |

| < 60 mm | < 60 mm | < 80×40 mm | ⌀ 20 mm | ⌀ 12 mm | ⌀ 10 mm | ⌀ 40 mm | ⌀ 25 mm | |

| < 80 mm | < 80 mm | < 100×60 mm | ⌀ 20 mm | ⌀ 16 mm | ⌀ 12 mm | ⌀ 40 mm | ⌀ 35 mm | ⌀ 25 mm |

| < 100 mm | < 100 mm | < 120×80 mm | ⌀ 25 mm | ⌀ 20 mm | ⌀ 12 mm | ⌀ 50 mm | ⌀ 40 mm | ⌀ 25 mm |

| < 120 mm | < 120 mm | < 160×80 mm | ⌀ 30 mm | ⌀ 25 mm | ⌀ 20 mm | ⌀ 60 mm | ⌀ 50 mm | ⌀ 40 mm |

| < 160 mm | < 160 mm | < 200×120 mm | ⌀ 40 mm | ⌀ 25 mm | ⌀ 20 mm | ⌀ 80 mm | ⌀ 50 mm | ⌀ 40 mm |

| < 200 mm | < 200 mm | < 260×140 mm | ⌀ 50 mm | ⌀ 30 mm | ⌀ 25 mm | ⌀ 100 mm | ⌀ 60 mm | ⌀ 50 mm |

Preparation for galvanizing

When delivering structures for galvanizing, pay special attention to:

A properly designed structure for hot-dip galvanizing.

Appropriate steel for hot-dip galvanizing.

Component dimensions suitable for the size of the galvanizing kettle.

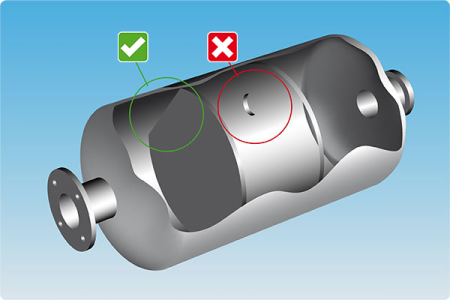

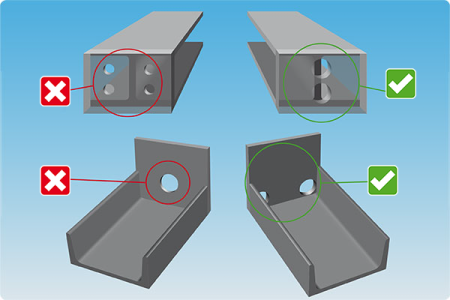

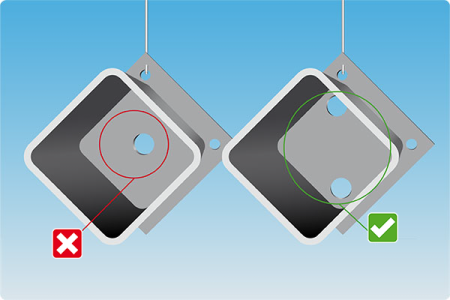

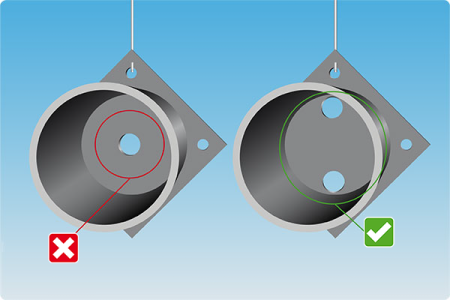

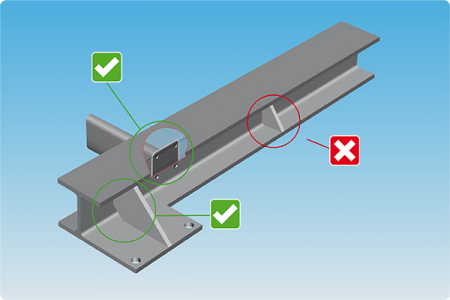

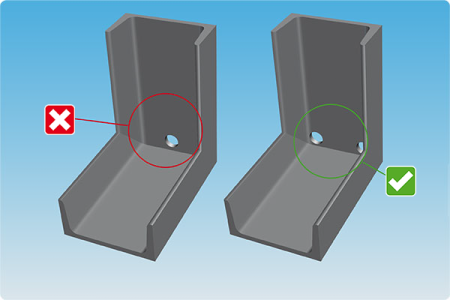

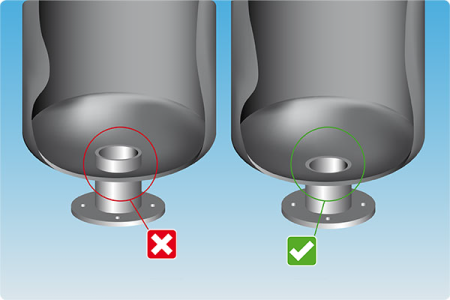

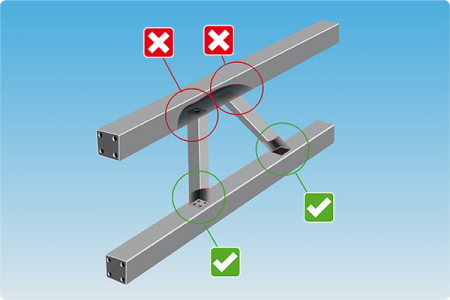

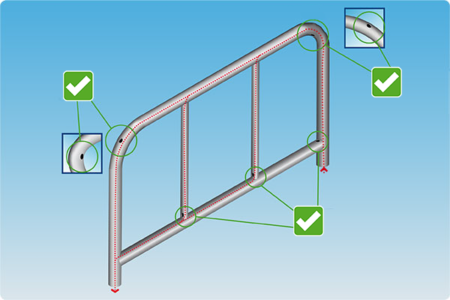

Ensure technological holes – venting and drainage.

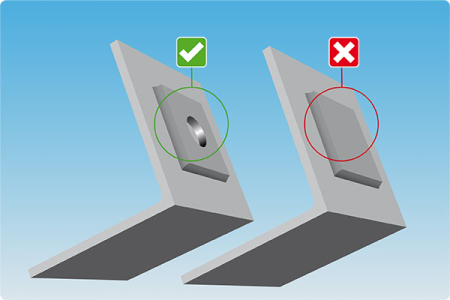

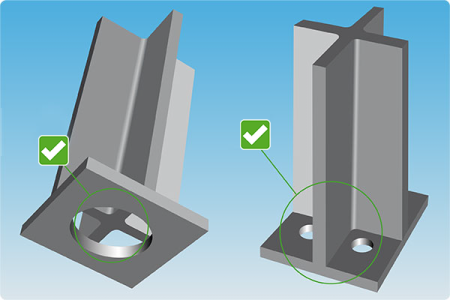

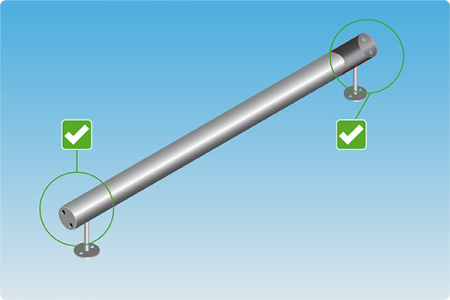

Prepare handles or holes for hanging the component.

Deliver structures free of contamination such as paint, oil, anti-spatter spray, etc.

Provide additional clearance for moving parts such as hinges, etc.

Check the tightness of the welds – this will prevent subsequent acid leakage.

Fabricate structures using materials with similar wall thicknesses.

Avoid designing overlapping (contact) surfaces.

Permanently protect areas that are not to be galvanized (e.g., threaded connections, fitted joints, areas prepared for subsequent welding, or other surfaces) against galvanizing, for example, with a two-component paint, preferably 48 hours before the hot-dip galvanizing process.