Steel is used in various fields and is among the most popular materials with a wide range of applications. Its surface requires special care due to its tendency to react with the natural environment and corrode. The galvanizing process allows a steel part to acquire a protective layer. This is sufficient for several decades of use without the risk of rust.

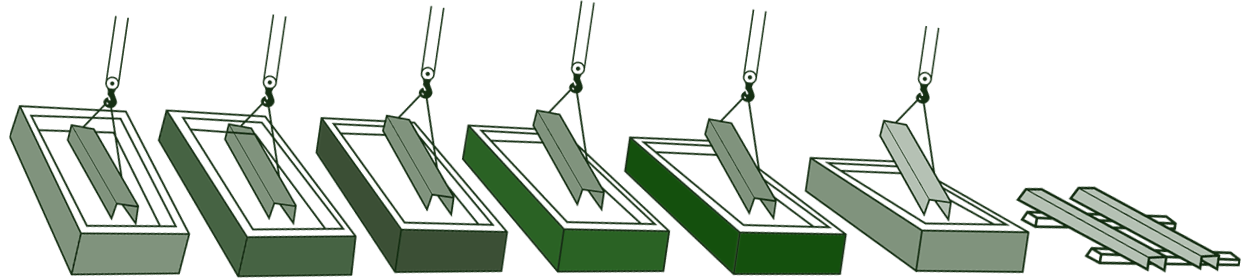

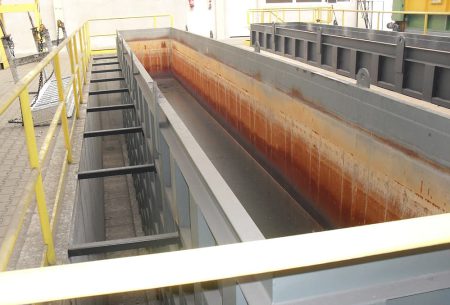

For this purpose, pre-treated steel parts are immersed in a hot zinc bath at a temperature of approximately 450°C as part of a multi-stage immersion method. An anti-corrosion protective coating is formed on the surface in the form of a zinc-iron alloy layer. The component is protected and requires no maintenance. This technique is also environmentally friendly.

See how to prepare an element for galvanizing

See how to prepare an element for galvanizing