Side walls bent with 1 sheet of sheet 4 mm with S355 steel with a height of 1,480 mm with walls

stiffening profiles - hot-dip galvanised

stiffening profiles - hot-dip galvanised

New 580/70 R38 wheels

Hot-dip galvanized drawbar made of 355 steel - alloy steel with increased strength

Wall brackets equipped with reinforced edge seal preventing damage to walls’ galvanised coating

Axles of the reputable company ADR

Technical data

Technical data

- Type / Variant / Version according to EU homologation N-1 910 71

- Administrative loading capacity 6,360 kg (7,360 kg with K80

harnass) - Technical loading capacity ~14360 kg*

- Gross vehicle weight rating according to PL regulations 20,000 kg (21,000 kg with K80 harnass)

- Gross vehicle weight rating according to Directive 2015/208

(only load on axles) 10,000 kg - Unladen mass ~ 6,640 kg

- Number of axles 1

- Adapter A2V adapter – 2 vertical drums

- Length 7,870 mm

- Width 2,910 mm

- Height 3,250 mm

- Length of loading space ext. (góra) 4,640 mm

- Width of loading box interior 1410 / 2,470 mm

- Height of loading box walls 1,480 mm

- Height of platform from base 1,345 mm

- Loading height 2,825 mm

- Floor/wall sheet thickness 3 / 4 mm

- Conveyor drive Hydraulic lock

- Adapter drive Mechanical from the PTO shaft

- Openable side walls No

* – unladen mass and loading capacity may vary depending on equipment

- Loading capacity (loading 5cm above the side walls) 12.7 m3 (heaped 15.5 m3)

- Track of wheels 2,155 mm

- Suspension rigid

- Max. vertical drawbar eye load 3,000 kg (4,000 kg with K80

harnass) - Drawbar coupling height – lower position 540 mm

- The height of the drawbar clutch – upper position 760 mm

- Max. tolerable axle load administrative 10,000 kg

(technical 17,000 kg) - Tyre size 580/70 R38

- Design speed 30 km/h

- Minimum demand for tractor power 88kW/120KM

- Spreading width depending on manure used ~18 – 24 m**

** – spreading width may differ from the specified width depending on the material used

Downloads

Downloads

Features and accessories

Features and accessories

- Side walls bent with 1 sheet of sheet 4 mm with S355 steel with a height of 1,480 mm with walls stiffening profiles – hot-dip galvanised

- A2V adapter – 2 balanced inclined vertical drums with bolted knives, with lime board, hot-dip galvanised

- Exchangeable floor made of hot-dip galvanised flat sheet

- Shock-absorbing, homologated, hot-dip galvanised drawbar with exchangeable hitch eye according to Regulation 55 UN ECE

- The drawbar is damped and positioned by means of hydraulic cylinders with two accumulators

- Hydraulic advance of conveyor with stepless regulation and overload valve

- Hot-dip galvanised hydraulic rear wall

- Hot-dip galvanised divided deflectors opened hydraulically

- Hot-dip galvanised front guard, meeting safety requirements

- Bolted drawbar diam. 50

- Hot-dip galvanised support frame made of elevated strength steel sheets

- Hydraulic shaft support partially hot-dip galvanised

- Hot-dip galvanised conveyor chain – 14×50 links

- Exchangeable, hot-dip galvanised conveyor strips made of metallurgical C65 profile

- Parking brake made with the assistance of spring membrane cylinders

- Hot-dip galvanised foldable exterior ladder with anti-skid steps, facilitating access to the load box

- Star wheels made of spheroidal graphite iron

- EU homologation

- Lighting installation connector cable with 7PIN 12V plug

- 12V lighting, homologated, for bulbs

- Pneumatic double-circuit brake system with manual braking force adjustment

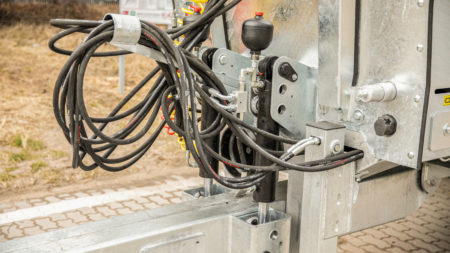

- Hydraulic installations made of galvanised steel tubes and flexible hoses

- Hydraulic connectors to tractor, type ISO 7241-1 DN 12.5

- New 580/70 R38 wheels

- Axles from the renowned ADR company, full beam with 150 mm square cross-section, 406 x 140 brake

- Other elements

- Two wheel chocks placed in galvanised pockets

- Articulated shaft for coupling to tractor

- Rigid suspension

- Drive shafts coupled to articulated PTO shafts equipped with clutch protecting the transmission: friction and one-way

- Exchangeable adapter blades

- Exchangeable, galvanised skids of fl oor conveyor strips

- Wood skids for conveyor chains under upper frame

- Floor conveyor powered by two transmissions, 4000 Nm each

- Hot-dip galvanised bracket for connectors, adjustable

- Wall brackets equipped with reinforced edge seal preventing damage to walls’ galvanised coating

- Rear wall opening height indicator

- Mudguards with flaps

Additional equipment

Additional equipment

- Full LED lighting

- Hydraulic quick-coupler with pressure neutralizer in hose

- Wide-angle articulated PTO shaft

Warning triangle (sign distinguishing slow-moving vehicle) - Digital Control – conveyor drive control, rear wall, drawbar, hydraulic drawbar support, hydraulic deflectors

- Conveyor’s hydraulic feed with electric control in tractor cabin

- K80 drawbar hitch (permitted drawbar eye load up to 4,000 kg)

- Hot-dip galvanised guard of inspection window

Check the machine rental offer

Check the machine rental offer