Cynkowana podłoga wykonana z blach o grubości 4mm

Dyszel typu „Y” z wymienną końcówką, homologowany zgodnie z Regulaminem 55 EKG ONZ (Reg. 55 UN ECE) oraz 167/2013*2015/208 ND

Rama cynkowana ogniowo (zabezpieczenie konstrukcji na zewnątrz i wewnątrz

profili), podłóżnice ramy wykonane z IPE 270

profili), podłóżnice ramy wykonane z IPE 270

Nowe koła 500/50-17

Wysuwana rama tylna przedłużająca powierzchnię ładunkową o ok. 1m (nie jest dozwolone poruszanie się po drogach publicznych z wysuniętą ramą tylną)

Osie renomowanej firmy ADR, pełna belka o przekroju kwadratowym 90 mm, hamulec 350x90

Technical data

Technical data

- Administrative Payload: ~ 19 400 kg*

- Technical Payload: ~ 19 400 kg*

- Permissible Gross Vehicle Weight (GVW): 24 000 kg

- Curb Weight: 4 760 kg*

- Number of Axles: 3

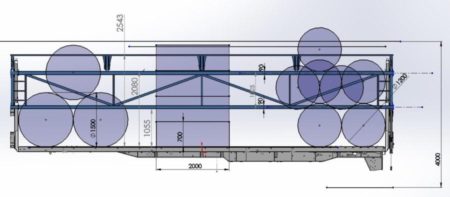

- Length – rear frame retracted / extended max.: 11 995 / 12 995 mm

- Width: 2 550 mm

- Height: ~ 2 545 mm

- Box Type: Platform

- Pallet Width: Yes

- Extendable rear frame: Yes

*- curb weight and payload may vary depending on the equipment

- Floor height from ground: ~ 1 110 mm

- Ladder height from floor: ~ 1 435 mm

- Load box width between edges: 2 415 mm

- Platform length: 10 040 mm

- Loading surface length top/bottom: 10 330 mm (+ approx. 1m max. with extended rear frame**)

- Loading area: 24.9 / 27.4** m2

- Floor sheet metal thickness: 4 mm

- Tire size: 500/50-17

- Wheel track: 1 900 mm

- Axle spacing: 1-2. 4 880mm, 2-3. 1 350 mm

- Drawbar coupling height – min: 335 mm

- Drawbar coupling height – max: 900 mm

- Transport/working speed: 40 km/h

- Suspension: parabolic leaf springs

- Cooperating tractor class: 88.2 kW / 120 HP

Downloads

Downloads

Features and accessories

Features and accessories

- Hot-dip galvanized floor made of 4 mm thick steel sheets

- “Y” type drawbar with replaceable end piece (homologated in accordance with Regulation 55 UN ECE and 167/2013*2015/208 ND)

- Bolted coupling eye fi 40

- 2 adjustable springs supporting the drawbar

- Hot-dip galvanized frame (protection of the structure outside and inside the profiles)

- Frame longitudinal members made of IPE 270

- Parking brake implemented using diaphragm spring actuators

- Edges on the frame side longitudinal members limiting load shifting

- Openings in the side longitudinal members and handles for securing load straps

- Hot-dip galvanized ladders at the front and rear of the platform with a height of 1 435 mm, made of closed profiles

- 2 central cables supporting the ladders

- Extendable rear frame extending the loading surface by approx. 1m*

- Homologated rear bumper, hot-dip galvanized

- Lighting installation connection cable with 7PIN 12V plug

- Full LED lighting

- Homologated two-line pneumatic brake system with automatic braking force regulator

- New wheels 500/50-17

- Axles from the renowned company ADR, solid beam with a square cross-section of 90 mm, brake 350×90

- Suspension on parabolic leaf springs

- Two wheel chocks placed in galvanized pockets

- Wheel mudguards on the last axle

* – driving on public roads with the rear frame extended is not permitted

Additional equipment

Additional equipment

- Side underrun protection (bicycle guards)

- Spare wheel winch with hot-dip galvanized wheel carrier

- Hydraulic installation for rear frame extension

- Hydraulic quick coupler with pressure eliminator in the line

- Spare wheel 500/50-17

- Surcharge for wheels 435/50 R 19.5

- Spare wheel 435/50 R 19.5

- Surcharge for wheels 500/50 R17

- Spare wheel 500/50 R17

- Manual hitch for the second trailer

- Warning triangle (slow-moving vehicle distinguishing sign)

- Drawbar eye 50mm

- Tool box

- Water tank + soap dispenser

- 1/4 mudguards on the first and second axle

Check the machine rental offer

Check the machine rental offer