Wall height 500 mm with thickness 2.5 mm, hot-galvanized

Central bolt-locking of walls (bottom sideboards)

Exterior ladder and steps inside cargo box - hot-galvanized - with anti-skid steps facilitating access to cargo box

Rigid drawbar for coupling with the top or bottom hitch of the tractor, with replaceable 40mm eye, drawbar homologated according to Regulation 55UN ECE

Hot-galvanized frame of cargo box

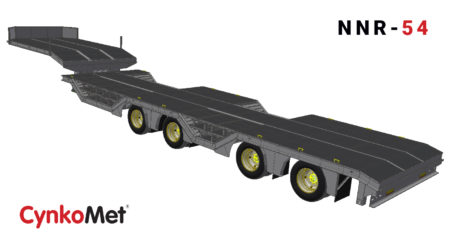

Technical data

Technical data

- Load capacity ~3,500 kg*

- Kerb weight (without wall extensions) ~1,360 kg*

- Length 4,720 mm

- Width 1,990 mm

- Height without extension ~1,575 mm

- Height with extension ~2,075 mm

- Cargo box dimensions (length/width/height) 3320x1810x500 (x 1,000 mm with extensions)

- cargo capacity 3m ³ (6m³ extensions)

- Height of floor above ground 1,075 mm

- Tire size 11.5/80-15.3

- Floor/wall sheet thickness 3/2.5 mm

- Track of wheels 1,500 mm

- Drawbar coupling height – bottom position 445 mm

- Drawbar coupling height – top position 770 mm

- Max. tolerable vertical load on drawbar 1,000 kg

- Transport/working speed 30 km/h

- Suspension rigid

- Class of cooperating tractor 30HP

- Tipping angle of the cargo box (backward/sideways) 45/50

Downloads

Downloads

Features and accessories

Features and accessories

- Wall height 500 mm with thickness 2.5 mm, hot-galvanized

- New 11.5/80-15.3 wheels

- Rigid drawbar for coupling with the top or bottom hitch of the tractor, with replaceable 40mm eye, drawbar homologated according to Regulation 55UN ECE,

- Homologated, hot-galvanized bumper

- Axles from the renowned ADR company, homologated (EU 2015/68), bar cross-section – square 70, brake size 300×60 306E, 6 M18x1.5 pins

- Central bolt-locking of walls (bottom sideboards)

- Exterior ladder and steps inside cargo box – hot-galvanized – with anti-skid steps facilitating access to cargo box

- Two wheel chocks placed in galvanized pockets

- Telescopic actuator with articulated suspensions, four-level with 1,300 mm pitch. Useful force at fourth level with diameter 105mm, at nominal pressure 16MPa = 138kN (~14T)

- Tipping installation protected against excessive box inclination by cut-off valve

- Maintenance support of cargo box, hot-galvanized

- Hot-galvanized frame of cargo box

- Main stringers of cargo box frame made of 160x60x4 closed profiles

- Cargo box floor with riveted and bolted sheets with a thickness of 3 mm

- Hot-dip galvanized bottom frame (protection of the structure on the exterior and interior of profiles), stringers of the frame made of steel sections

- 12V lighting, homologated, rear bulb lamps, LED perimeter lighting

- Hydraulic tipping installation of cargo box made of galvanized steel tubes and flexible hoses

- Hydraulic connectors to tractor, type ISO 7241-1 DN 12.5

- Lighting installation connector cable with 7PIN 12V plug

- Homologated, double-circuit, pneumatic brake system with manual braking force adjustment from HALDEX.

- Parking handbrake with crank

- Grain chute, hot-galvanized, with blockade in the rear wall

- Straight drawbar support with collapsible steel wheel, partially hot-galvanized

Additional equipment

Additional equipment

- Spare wheel hanger, hot-galvanized

- Hot-galvanized tarpaulin frame made of 40x40x3 closed profiles

- Hot-galvanized 500 mm wall extensions, thickness 2.5 mm

- Chute for precise tipping, hot-galvanized

- Hot-galvanized 1000 mm mesh wall extensions (no homologation)

- Full LED lighting

- Homologated, hydraulic double-circuit brake system with manual braking force adjustment

- 11.5/80-15.3 spare wheel

- Laced tarpaulin

- Hydraulic quick-coupler with pressure neutralizer in hose

- Warning triangle (sign distinguishing slow-moving vehicle)

- DUPLEX – painted set of walls

- DUPLEX – painted set of extensions

Check the machine rental offer

Check the machine rental offer