Wysokość ścian 1000 mm o grubości 2 mm, cynkowane ogniowo

Dyszel dwupołożeniowy do łączenia z dolnym lub górnym zaczepem ciągnika z wymiennyn okiem 50mm

Drabinka zewnętrzna oraz stopki wewnątrz skrzyni ładunkowej cynkowane ogniowo, ze stopniami antypoślizgowymi ułatwiające dostęp do skrzyni ładunkowej

Rama dolna cynkowana ogniowo posiadająca podłużnice z profili 200x80x6 połączone profilami 160x80x6 oraz 80x60x4, z belką dyszla wykonaną z blachy 8 mm

Nowe koła 550/60-22.5

Osie renomowanej firmy ADR, homologowane (EU 2015/68)

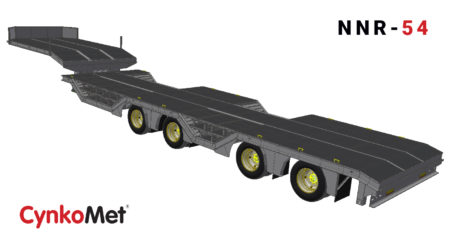

Technical data

Technical data

- Technical (designed) maximum permissible gross weight rating 19,000 kg

- Gross vehicle weight rating 16,000 kg

- including on axles max. 13,000 kg

- including on drawbar max. 3,000 kg

- Load capacity ~10,320 kg*

- Unladen mass ~5,680 kg*

Loading surface 10.6 m²

cargo capacity 10.6 m³

Width of cargo box interior 2,080 mm

Length of cargo box interior 5090 mm

Box wall height 1000 mm

Overall dimensions (length/width/height) 8320/2460/~3035 mm

Floor/wall sheet thickness 3 mm / 2 mm

Height of platform from base ~1505 mm

Track of wheels 1800 mm

Suspension tandem – parabolic springs

Drawbar eye load 3,000 kg

Tire size 550/60-22.5**

Max load on axle 1 8,000 kg

Max load on axle 2 8,000 kg

Design speed 40 km/h

Minimum demand for tractor power 74/100 (kW/HP)

Drawbar coupling height – bottom position 505

Drawbar coupling height – top position 1150

Spreading width depending on manure or lime used ~12 m**

Downloads

Downloads

Features and accessories

Features and accessories

- Walls with height 1000 mm, with sheet thickness 2 mm, hot-dip galvanized

- New 550/60-22.5 wheels (no EU homologation)

- A2V adapter – 2 balanced vertical drums with exchangeable, hot-galvanized cutters

- Hot-galvanized adapter with deflector

- Rigid drawbar for coupling with bottom or top tractor hitch, with exchangeable 50 mm ear,

homologated according to Regulation 55UN ECE - Hot-galvanized drawbar made of 355 steel – enhanced strength alloy steel

- Axles from the renowned ADR company, homologated (EU 2015/68), bar cross-section – square 90,

brake size 400×80 408E, 8 M20x1.5 pins - Exterior ladder and steps inside cargo box – hot-galvanized – with anti-skid steps facilitating access

to cargo box - Hot-galvanized bottom frame with stringers made of 200x80x6 profiles joined by 160x80x6 and

80x60x4 profiles, with drawbar made of 8 mm sheet - Top frame, hot-galvanized, welded from bars made of 160x60x4 profiles and cross-bars made of

sheet 4, 6 and 8 mm thick, stringers made of metallurgical 200 channel section - Exchangeable riveted floor made of hot-galvanized flat sheet

- Exchangeable, galvanized skids of floor conveyor strips

- Lighting installation connector cable with 7PIN 12V plug

- 12V lighting, homologated, rear bulb lamps, LED front lamps

- Hot-galvanized rear hydraulic wall raised by two actuators with pitch 1100 mm

- Hydraulic advance of conveyor with stepless regulation and overload valve

- Hot-galvanized 14×50 conveyor chain

- Exchangeable, hot-galvanized conveyor strips made of metallurgical C65 profile

- Distance piece limiting divergence of chain throughout entire length

- Floor conveyor powered by two transmissions, 4000 Nm each

- Conveyor star wheels made of spheroidal graphite iron

- Hydraulic installations made of galvanized steel tubes and flexible hoses

- Hydraulic connectors to tractor, type ISO 7241-1 DN 12.5

- Drive shafts coupled to articulated PTO shafts equipped with clutches protecting the transmission: friction and one-way clutches

- Homologated pneumatic, double-circuit brake system with automatic braking force adjustment from

HALDEX. - Parking handbrake with crank

- Hydraulic drawbar support

- Two wheel chocks placed in galvanized pockets

- Hot-galvanized front mesh, meeting safety requirements (according to standard PN-EN 690:2014-

02), with folding mechanism for transport purposes

Additional equipment

Additional equipment

- Hot-galvanized 800 mm wall extensions with hydraulic rear wall

- Conveyor’s hydraulic feed with electric control in tractor cabin

- Hydraulic defl ector control system equipped with hydraulic distributor with solenoid valves and

electric controller - Hydraulic brake installation

- Full LED lighting

- Hydraulic quick-coupler with pressure neutralizer in hose

- New 600/50-22.5 wheels

- Wide-angle articulated PTO shaft

- Warning triangle

- Ball hitch 80 mm

Check the machine rental offer

Check the machine rental offer