Wysokość ścian 2x800 mm o gr 2,5 mm, cynkowane ogniowo

Dzielone ściany boczne

Nowe koła 385/65-22.5

Osie renomowanej firmy ADR, homologowane (EU 2015/68), przekrój belki - kwadrat 90, rozmiar hamulca 406x120 412E, 8 szpilek M20x1,5

Cynkowany ogniowo, amortyzowany dyszel, homologowany zgodnie z Rozporządzeniem UE 2015/208, oczko 50

Hydrauliczna podpora dyszla z wbudowanym zamkiem hydraulicznym

Centralne ryglowanie ścian (borty dolne)

Drabinka zewnętrzna oraz stopki wewnątrz skrzyni ładunkowej cynkowana ogniowo, ze stopniami antypoślizgowymi ułatwiające dostęp do skrzyni ładunkowej

Rama skrzyni ładunkowej cynkowana ogniowo

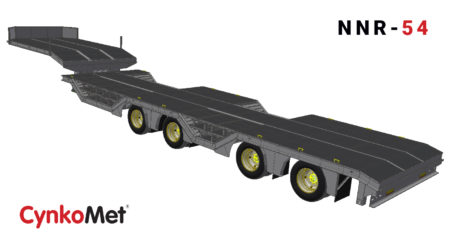

Technical data

Technical data

Technically (design) permissible total weight rating 21,000 kg

Gross vehicle weight rating ~16,900 kg

including on axles max. 13,900 kg

including on drawbar max. 3,000 kg

Load capacity ~12,000 kg*

Unladen mass ~4,900 kg*

Length 7,250 mm

Width 2,550 mm

Height without extension / with 1 extension / with 2 extensions ~ 2,096 / 2,596 / 3,100 mm

Length of cargo box interior 5,130 mm

Width of cargo box interior 2,420 mm

Box wall height 1,000 mm

Loading surface 12.4 m²

Loading volume standard / with 1 extension / with 2 extensions 6.2 / 12.3 / 18.5 m³

Drawbar coupling height - bottom position 380 mm

Drawbar coupling height - central/ top position 610/860 mm

Coupling height of rear hitch (optional) 870 mm

Height of floor above ground ~1,565 mm

Tire size 385/65 R22.5

Floor/wall sheet thickness 4/2.5 mm

Track of wheels 1,900 mm

Transport/working speed 40 km/h

Suspension parabolic springs in tandem configuration

Class of cooperating tractor 100 HP

Tipping angle of the cargo box (backward / sideways) 45/50

Tipping system * - unladen weight and loading capacity may differ depending on the trailer's equipment three-way

Downloads

Downloads

Features and accessories

Features and accessories

- Wall height 2×500 mm with thickness 2.5 mm, hot-galvanized

- Partitioned side walls

- New 385/65-22.5 wheels

- Pallet width

- Axles from the renowned ADR company, homologated (EU 2015/68), bar cross-section – square 90,

brake size 406×120 412E, 8 M20x1.5 pins - Hot-galvanized, shock-absorbing drawbar, homologated according to EU Directive 2015/208, 50mm

eye - Hydraulic drawbar support with built-in hydraulic lock

- Central bolt-locking of walls (bottom sideboards)

- Exterior ladder and steps inside cargo box – hot-galvanized – with anti-skid steps facilitating access

to cargo box - Two wheel chocks placed in galvanized pockets

- Telescopic actuator with articulated suspensions, five-level with 1980 mm pitch. Useful force at fifth level with diameter 140 mm, at nominal pressure 20MPa = 307.9kN (31.4T)

- Tipping installation protected against excessive box inclination by cut-off valve

- Maintenance support of cargo box, hot-galvanized

- Side wall links

- 12V lighting, homologated, rear bulb lamps, LED perimeter lighting, rear socket for connection to

second trailer - Lighting installation connector cable with 7PIN 12V plug

- Homologated, double-circuit, pneumatic brake system with automatic braking force adjustment from HALDEX, with output for second trailer.

- Parking handbrake with crank

- Hot-galvanized frame of cargo box

- Main stringers of cargo box frame made of closed profiles with variable cross-section, made from

6mm sheet. Profile cross-section at highest point 110×300 mm - Grain chute, hot-galvanized, with blockade in the rear wall

- Hot-dip galvanized bottom frame (protection of the structure on the exterior and interior of profiles),

stringers of the frame made of 250x150x8 closed sections - Rear hydraulic and brake output to the second trailer

- Hydraulic tipping installation of cargo box made of galvanized steel tubes and flexible hoses

- Hydraulic connectors to tractor, type ISO 7241-1 DN 12.5

- Hot-galvanized rear bumper, homologated according to Regulations 2015/504 and 167/2013

Additional equipment

Additional equipment

- Set of hot-galvanized 500 mm wall extensions, thickness 2.5 mm

- Spare wheel winch with hot-galvanized wheel hanger

- Hot-galvanized tarpaulin frame made of 40x40x3 closed profi les

- Chute for precise tipping, hot-galvanized

- Hot-galvanized work platform

- Side underrun guards

- Ball hitch tension member dia. 80Full LED lighting

- Homologated, hydraulic double-circuit brake system with automatic braking force adjustment

- Surcharge for 550/60 R22.5 wheels

- 385/65 R22.5 spare wheel

- 550/60 R22.5 spare wheel

- Roll-up tarpaulin

- Manual hitch for second trailer

- Automatic hitch for second trailer

- Water tank + soap dispenser

- Toolbox

- Warning triangle (sign distinguishing slow-moving vehicle)

- Hydraulic quick-coupler with pressure neutralizer in hose

- DUPLEX – painted set of walls

- DUPLEX – painted set of extensions

Check the machine rental offer

Check the machine rental offer