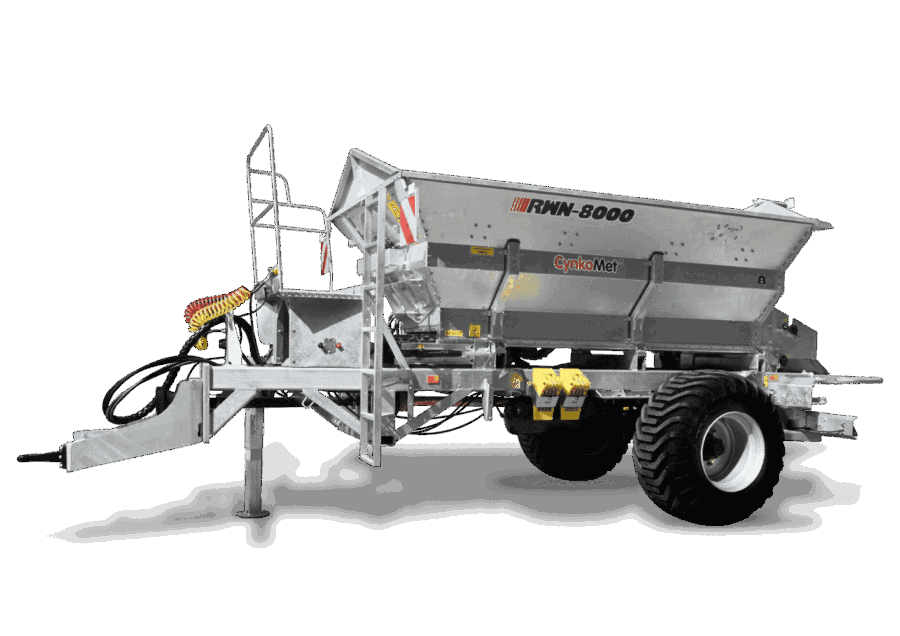

The walls are 1000 mm high, with a sheet thickness of 3 mm, hot-dip galvanized

Spreading width depending on the applied fertilizers or lime ~ 8-10 m

New 600/50-22.5 wheels

rigid drawbar to be connected to the upper hitch of the tractor with a replaceable eye

Axle from renowned ADR company

Hot-dip galvanized work platform with non-slip steps for easy access to the load box

Hot-dip galvanised hydraulic drawbar support

Technical data

Technical data

- Load capacity ~8,000 kg*

- Gross vehicle weight rating according to PL

regulations 12,300 kg - Unladen mass ~ 4,300 kg (with covers and tarpaulin)*

- Number of axles 1

- Adapter + 2 spreading discs

- Conveyor drive Wheel drive

- Length 6,740 mm

- Width without guards / with guards ~ 2,520 / 2,780 mm

- Height 2,660 mm

- Length of the interior loading space top / bottom 3,445 / 2,790 mm

- The width of the interior loading box top / bottom 2,000 / 800 mm

- Height of loading box walls 1,030 mm

- Height of platform from base 1,210 mm

- Loading height 2,240 mm

- Floor/wall sheet thickness 5 / 3 mm

* – unladen mass and loading capacity may vary depending on equipment

- cargo capacity 5.5 m3

- Track of wheels 1900 mm

- Suspension parabolic springs

- Max. vertical drawbar eye load 3,000 kg

- Drawbar coupling height 925 mm

- Max. tolerable axle load 9,300 kg

- Tyre size 600/50-22.5

- Design speed 40 km/h

- Minimum demand for tractor power 74kW/100KM

- Spreading width depending on manure used ~10-14 m**

** – spreading width may differ from the specified width depending on the material used

Downloads

Downloads

Features and accessories

Features and accessories

- Agitators for mineral fertilisers located in the loading box and driven from the PTO shaft

- Hydraulic distributor controlled electronically from the control panel

- Hot-dip galvanised hydraulic gate valve with protection

- Weighing system based on strain gauges integrated with a readable display

- A set of cameras inside and outside the load box

- Gate open indicator

- Hot-dip galvanised load box welded from sheets with a thickness of 3 and 5mm

- The floor of the load box is made of 5mm sheet metal

- The lower frame is hot-dip galvanised – stringers made of rectangular profiles 160×80

- Bolted hitch harnass diam. 40

- Speed-dependent mechanical floor conveyor driven by driving wheel Feed speed depends on travel speed.

- Heavy-duty gear driven floor conveyor.

- Transmission of drive through a set of PTO shafts with overload and one-way clutches

- AktivGruda active material shredding system

- The pressure of the drive wheel of the floor conveyor is hydraulically controlled

- Possibility to drive the floor conveyor with the PTO shaft when parked

- Automatic floor chain tensioning system

- Hot-dip galvanised 2-disc adapter with tilt adjustment and adjustable paddles

- Adapter discs mechanically driven by PTO shaft 540 rpm

- Own hydraulic system with pump, filter and tank

- Hot-dip galvanised hydraulic drawbar support

- Conveyor chain – links 14×50

- Conveyor slats made of C50 channel sections

- Parking brake with parking and releasing valve and diaphragm-spring actuators

- Star wheels made of spheroidal graphite iron

- Working platform

- Design protecting the box and floor conveyor from foreign objects

- Installations

- Lighting installation connector cable with 7PIN 12V plug

- 12V lighting, homologated, LED

- Pneumatic two-line braking system with ALB

- Hydraulic installations made of galvanised steel tubes and flexible hoses

- Hydraulic connectors to tractor, type ISO 7241-1 DN 12.5

- Chassis

- New 600/50-22.5 wheels

- Axle from renowned ADR company, full beam with 90 mm square cross-section, 400×80 brake

- Other elements

- Two wheel chocks placed in galvanised pockets

- Articulated shaft for coupling to tractor

- Parabolic leaf spring suspension

- Bracket for connectors, hot-dip galvanised

Additional equipment

Additional equipment

- Rolled tarpaulin with a foldable hot-dip galvanised frame

- Installations

- LED work lights

- Hydraulic quick coupler with pressure eliminator in the hose (support foot)

- Other equipment

- Wide-angle articulated PTO shaft

- Hitch rod diam. 50

- Warning triangle (sign distinguishing slow-moving vehicle)

- Additional display for weighing system

- Cover for spreading road grit and salt

- 10m wide fold-out dust covers

Check the machine rental offer

Check the machine rental offer