Wall height 800 mm with thickness 2mm, hot-galvanized - split side walls

Wall extensions, height 800 mm with thickness 2 mm, hot-galvanized - split side wall extensions

Central bolt-locking of walls (bottom sideboards)

Exterior ladder and steps inside cargo box - hot-galvanized - with anti-skid steps facilitating access

to cargo box

to cargo box

“Y”-type drawbar with exchangeable tip, homologated according to Regulation 55 UN ECE and

167/2013*2015/208 ND

167/2013*2015/208 ND

New 385/65 R22.5 wheels

Axles from renowned ADR company, full beam with 90 mm square cross-section, 406x120 brake

Two wheel chocks placed in galvanized pockets

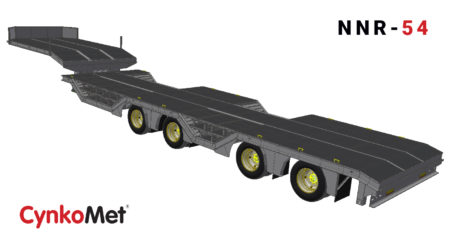

Technical data

Technical data

- Type / Variant / Version according to EU homologation T-1 B21 71

- Administrative loading capacity ~ 12,840 kg*

- Technical loading capacity 14,000 kg

- Gross vehicle weight rating according to PL regulations 18,000 kg

- Gross vehicle weight rating according to Directive 2015/208 (only load on axles) 18,000 kg

- Kerb weight (without wall extensions) ~5,160 kg* (with extensions – standard)

- Number of axles 2

- Length 7,350 mm

- Width 2,550 mm

- Height without extensions ~2,175 mm

- Height with extensions ~2,975 mm

- Box type Side-wall, pallet type

- Length of cargo box interior 5,140 mm

- Width of cargo box interior front/rear 2,430 mm

- Height of box walls (without extensions) 1,600 mm (800+800)

- Height of platform from base ~1,375 mm

- Floor/wall sheet thickness 5 / 2 mm

* – masa własna i ładowność mogą się różnić w zależności od wyposażenia przyczepy

- Loading surface 12.5 m2

- Loading capacity – without extensions (with extensions) 10 m3 (20 m3)

- Track of wheels 1,900 mm

- Wheelbase 3,460 mm

- Suspension parabolic springs

- Drawbar coupling height – min. 480 mm

- Drawbar coupling height – max. 1,190 mm

- Max. tolerable vertical load on axle 1. 9000 kg 2. 9,000 kg

- Tire size 385/65-22.5

- Design speed 40 km/h

- Minimum demand for tractor power 73.5 kW / 100 HP

- Tipping angle of the cargo box (backward / sideways) 45 / 50

- Tipping system three-way

Downloads

Downloads

Features and accessories

Features and accessories

- Wall height 800 mm with thickness 2mm, hot-galvanized – split side walls

- Wall extensions, height 800 mm with thickness 2 mm, hot-galvanized – split side wall extensions

- Central bolt-locking of walls (bottom sideboards)

- Exterior ladder and steps inside cargo box – hot-galvanized – with anti-skid steps facilitating access

to cargo box - Maintenance support of cargo box, hot-galvanized

- “Y”-type drawbar with exchangeable tip, homologated according to Regulation 55 UN ECE and

167/2013*2015/208 ND - Bolted hitch tension member dia. 40

- Hot-galvanized frame of cargo box

- Main stringers (with variable cross-section) of cargo box frame made of bent high-strength sheets

6mm thick. Profile cross-section at highest point 110×300 mm - Galvanized cargo box floor welded out of two sheets with a thickness of 5 mm, bolted and riveted

- Hot-dip galvanized bottom frame (protection of the structure on the exterior and interior of profiles),

stringers of the frame made of 250x150x8 and 150x150x8 closed sections - Parking handbrake with crank

- Grain chute, hot-galvanized, with blockade in the rear wall

- 2 regulated springs supporting drawbar

- Homologated, hot-galvanized bumper

- Side wall links

- Pallet width

- Tipping installation protected against excessive box inclination by cut-off valve

- Lighting installation connector cable with 7PIN 12V plug

- 12V lighting, homologated, rear bulb lamps, LED perimeter lighting

- Hydraulic tipping installation of cargo box made of galvanized steel tubes and flexible hoses

- Hydraulic connectors to tractor, type ISO 7241-1 DN 12.5

- Homologated, double-circuit, pneumatic brake system with automatic braking force adjustment, with

output for second trailer. - Rear hydraulic, electrical and brake output to the second trailer

- New 385/65 R22.5 wheels

- Axles from renowned ADR company, full beam with 90 mm square cross-section, 406×120 brake

- Parabolic leaf spring suspension

- Two wheel chocks placed in galvanized pockets

- Telescopic actuator with articulated suspensions, five-level with 1980 mm pitch. Useful force at fifth

level with diameter 140 mm, at nominal pressure 20MPa = 307.9kN (31.4T) - Wheel fenders

Additional equipment

Additional equipment

- Spare wheel winch with hot-galvanized wheel hanger

- Hot-galvanized tarpaulin frame made of 40x40x3 closed profi les

- Chute for precise tipping, hot-galvanized

- Hot-galvanized work platform

- Full LED lighting

- Homologated, hydraulic double-circuit brake system with automatic braking force adjustment

- 385/65 R22.5 “new” spare wheel

- Roll-up tarpaulin

- Hydraulic quick-coupler with pressure neutralizer in hose

- Warning triangle (sign distinguishing slow-moving vehicle)

- DUPLEX – painted set of walls

- DUPLEX – painted set of extensions

- Drawbar eye 50mm

- Set of side (bicycle) guards

- Automatic hitch for second trailer

- Manual hitch for second trailer

- Water tank + soap dispenser

- Toolbox

Check the machine rental offer

Check the machine rental offer