Side walls bent with 1 sheet of sheet 3 mm with S355 steel with a height of 800 mm with walls

stiffening profiles - hot-dip galvanised

stiffening profiles - hot-dip galvanised

Side wall stiffening profile

A4VS adapter - 4 inclined vertical worm drums with bolted knives, with discs and lime board - hotdip galvanised

Two-position drawbar for coupling with the top or bottom hitch of the tractor, with replaceable 50

mm eye, drawbar homologated according to Regulation 55 UN ECE

mm eye, drawbar homologated according to Regulation 55 UN ECE

Top and bottom frame hot-dip galvanized (structure protected on exterior and interior of profiles

Straight drawbar support with collapsible steel wheel, partially hot-dip galvanised

New 400/60-15.5 wheels

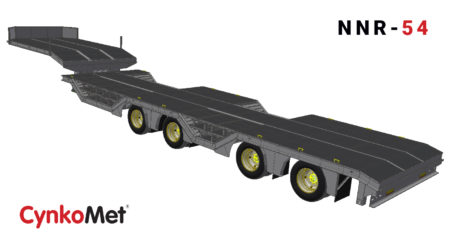

Technical data

Technical data

- Type / Variant / Version according to EU homologation N-2 320 11

- Administrative loading capacity ~5780 kg*

- Technical loading capacity ~6,000 kg*

- Gross vehicle weight rating according to PL regulations 9,800 kg

- GVWR according to Directive 2015/208 (only load on axles) 7,300 kg

- Unladen mass ~ 4,020 kg*

- Number of axles 2 – tandem

- Adapter A4VS adapter – 4 vertical drums

- Length 6,525 mm

- Width 2,430 mm

- Height 2,775 mm

- Length of loading space ext. (góra) 4,300 mm

- Width of loading box interior 2,070 / 2,150 mm

- Height of loading box walls 800 mm

- Height of platform from base 1,330 mm

- Loading height 2,130 mm

- Floor/wall sheet thickness 3/3 mm

- Conveyor drive Hydraulic lock

- Adapter drive Mechanical from the PTO shaft

- Openable side walls No

* – unladen mass and loading capacity may vary depending on equipment

- Loading capacity (loading 5cm above the side walls) 7.2 m3

Track of wheels 1,700 mm

Suspension Tandem – parabolic springs

Max. Drawbar eye load 2,500 kg

Drawbar coupling height – bottom position 390 mm

Drawbar coupling height – top position 1,030 mm

Max. tolerable axle load 1. 3,650 kg / 2 – 3,650 kg

Tyre size 400/60 15.5

Design speed 40 km/h

Minimum demand for tractor power 59kW/80KM

Spreading width depending on manure used ~6-8 m**

** – spreading width may differ from the specified width depending on the material used

Downloads

Downloads

Features and accessories

Features and accessories

- Side walls bent with 1 sheet of sheet 3 mm with S355 steel with a height of 800 mm with walls stiffening profiles – hot-dip galvanised

- A4VS adapter – 4 inclined vertical worm drums with bolted knives, with discs and lime board – hotdip galvanised

- Exchangeable floor made of hot-dip galvanised flat sheet

- Two-position drawbar for coupling with the top or bottom hitch of the tractor, with replaceable 50 mm eye, drawbar homologated according to Regulation 55 UN ECE

- Hydraulic advance of conveyor with stepless regulation and overload valve

- Hot-dip galvanised hydraulic rear wall

- Hot-dip galvanised adapter cover

- Hot-dip galvanised front guard, meeting safety requirements

- Bolted drawbar diam. 50

- Top and bottom frame hot-dip galvanised (structure protected on exterior and interior of profiles)

- Straight drawbar support with collapsible steel wheel, partially hot-dip galvanised

- hot-dip galvanised conveyor chain, link diameter 11 mm

- Replaceable hot-dip galvanised conveyor slats

- Parking handbrake with crank

- Hot-dip galvanised removable exterior ladder with anti-skid steps, facilitating access to the load box

- Star wheels made of spheroidal graphite iron

- EU homologation

- Lighting installation connector cable with 7PIN 12V plug

- 12V lighting, homologated, with bulbs, LED perimeter lighting

- Pneumatic two-line braking system with ALB

- Hydraulic installations made of galvanised steel tubes and flexible hoses

- Hydraulic connectors to tractor, type ISO 7241-1 DN 12.5

- Chassis

- New 400/60-15.5 wheels

- Axles from renowned ADR company, full beam with 80 mm square cross-section, 300×60 brake

Additional equipment

Additional equipment

- Hot-dip galvanised volume extensions with a hydraulic rear hatch – height 800 mm * (* it is not

possible to mount the extensions together with the adapter) - Additional hydraulic distributor for tractors with two hydraulic outlets – hydraulic control of the rear

wall, hydraulic drawbar support, on/off fl oor conveyor drive. - Hydraulic drawbar support

- Deflector

- Adapter blades made of high-strength steel

- Adapter A2V – 2 vertical inclined screw drums with bolted knives, with plates and a counter for lime, with a defl ector, hot-dip galvanised

- Installations

- Full LED lighting

- Hydraulic quick-coupler with pressure neutralizer in hose

- Homologated, hydraulic double-circuit brake system with automatic braking force adjustment

- Chassis

- Other equipment

- Wide-angle articulated PTO shaft

- Warning triangle

- Digital control – conveyor drive control, rear wall, volume hatch, hydraulic drawbar support

- Conveyor’s hydraulic feed with electric control in tractor cabin

- Hitch tension member K80

Check the machine rental offer

Check the machine rental offer